A Cross-Platform FOC implementation for BLDC and Stepper motors

based on the Arduino IDE and PlatformIO

We live in very exciting times 😃! BLDC motors are entering the hobby community more and more and many great projects have already emerged leveraging their far superior dynamics and power capabilities. BLDC motors have numerous advantages over regular DC motors but they have one big disadvantage, the complexity of control. Even though it has become relatively easy to design and manufacture PCBs and create our own hardware solutions for driving BLDC motors the proper low-cost solutions are yet to come. One of the reasons for this is the apparent complexity of writing the BLDC driving algorithms, Field oriented control (FOC) being an example of one of the most efficient ones.

The solutions that can be found on-line are almost exclusively very specific for certain hardware configuration and the microcontroller architecture used.

Additionally, most of the efforts at this moment are still channeled towards the high-power applications of the BLDC motors and proper low-cost and low-power FOC supporting boards are very hard to find today and even may not exist.

Therefore this is an attempt to:

- 🎯 Demystify FOC algorithm and make a robust but simple Arduino library: Arduino SimpleFOClibrary

- Support as many motor + sensor + driver + mcu combinations out there

- 🎯 Develop modular and easy to use FOC supporting BLDC driver boards

- For official driver boards see SimpleFOCBoards

- Many many more boards developed by the community members, see SimpleFOCCommunity

NEW RELEASE 📢 : SimpleFOClibrary v2.3.3

- Teensy4

- stm32

- KV rating calculation fix #347

- Much more performant Space Vector PWM calculation #340

- And much more:

- See the complete list of bugfixes and new features of v2.3.3 fixes and PRs

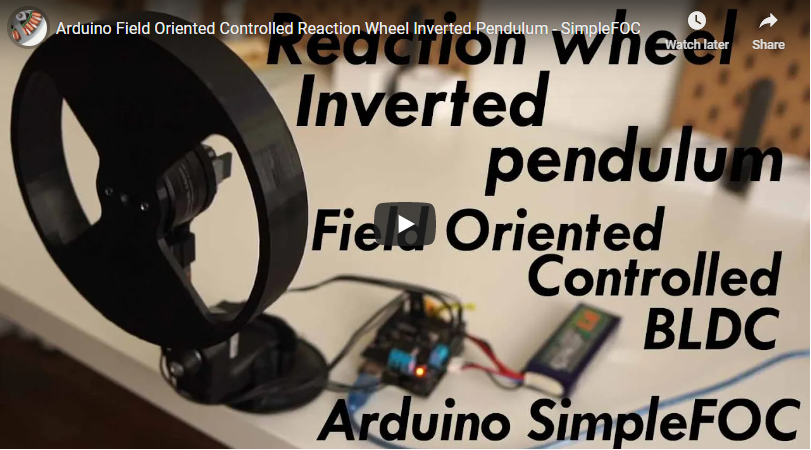

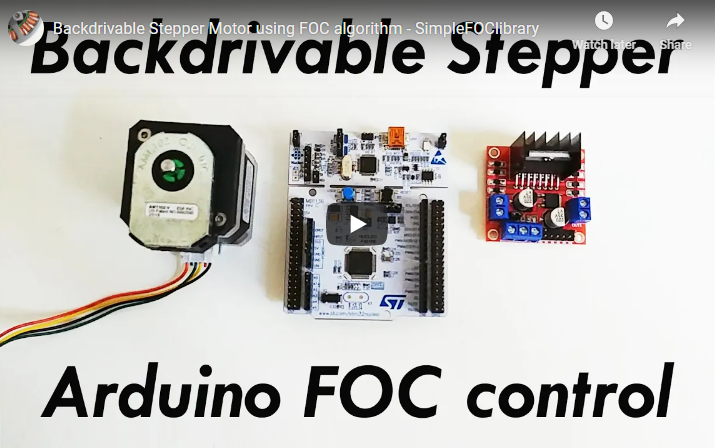

This video demonstrates the SimpleFOClibrary basic usage, electronic connections and shows its capabilities.

- Easy install:

- Arduino IDE: Arduino Library Manager integration

- PlatformIO

- Open-Source: Full code and documentation available on github

- Goal:

- Support as many sensor + motor + driver + current sense combination as possible.

- Provide the up-to-date and in-depth documentation with API references and the examples

- Easy to setup and configure:

- Easy hardware configuration

- Each hardware component is a C++ object (easy to understand)

- Easy tuning the control loops

- SimpleFOCStudio configuration GUI tool

- Built-in communication and monitoring

- Cross-platform:

- Seamless code transfer from one microcontroller family to another

- Supports multiple MCU architectures:

- Arduino: UNO R4, UNO, MEGA, DUE, Leonardo, Nano, Nano33 ....

- STM32

- ESP32

- Teensy

- many more ...

Full API code documentation as well as example projects and step by step guides can be found on our docs website.

Depending on if you want to use this library as the plug and play Arduino library or you want to get insight in the algorithm and make changes there are two ways to install this code.

The simplest way to get hold of the library is directly by using Arduino IDE and its integrated Library Manager.

- Open Arduino IDE and start Arduino Library Manager by clicking:

Tools > Manage Libraries.... - Search for

Simple FOClibrary and install the latest version. - Reopen Arduino IDE and you should have the library examples in

File > Examples > Simple FOC.

- Go to the github repository

- Click first on

Clone or Download > Download ZIP. - Unzip it and place it in

Arduino Librariesfolder. Windows:Documents > Arduino > libraries. - Reopen Arduino IDE and you should have the library examples in

File > Examples > Simple FOC.

- Open terminal and run

cd #Arduino libraries folder

git clone https://github.com/simplefoc/Arduino-FOC.git- Reopen Arduino IDE and you should have the library examples in

File > Examples > Simple FOC.

For all the questions regarding the potential implementation, applications, supported hardware and similar please visit our community forum or our discord server.

It is always helpful to hear the stories/problems/suggestions of people implementing the code and you might find a lot of answered questions there already!

Please do not hesitate to leave an issue if you have problems/advices/suggestions regarding the code!

Pull requests are welcome, but let's first discuss them in community forum!

If you'd like to contribute to this project but you are not very familiar with github, don't worry, let us know either by posting at the community forum , by posting a github issue or at our discord server.

If you are familiar, we accept pull requests to the dev branch!

This is a simple Arduino code example implementing the velocity control program of a BLDC motor with encoder.

NOTE: This program uses all the default control parameters.

#include <SimpleFOC.h>

// BLDCMotor( pole_pairs )

BLDCMotor motor = BLDCMotor(11);

// BLDCDriver( pin_pwmA, pin_pwmB, pin_pwmC, enable (optional) )

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11, 8);

// Encoder(pin_A, pin_B, CPR)

Encoder encoder = Encoder(2, 3, 2048);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

void setup() {

// initialize encoder hardware

encoder.init();

// hardware interrupt enable

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// power supply voltage [V]

driver.voltage_power_supply = 12;

// initialise driver hardware

driver.init();

// link driver

motor.linkDriver(&driver);

// set control loop type to be used

motor.controller = MotionControlType::velocity;

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

}

void loop() {

// FOC algorithm function

motor.loopFOC();

// velocity control loop function

// setting the target velocity or 2rad/s

motor.move(2);

}You can find more details in the SimpleFOC documentation.

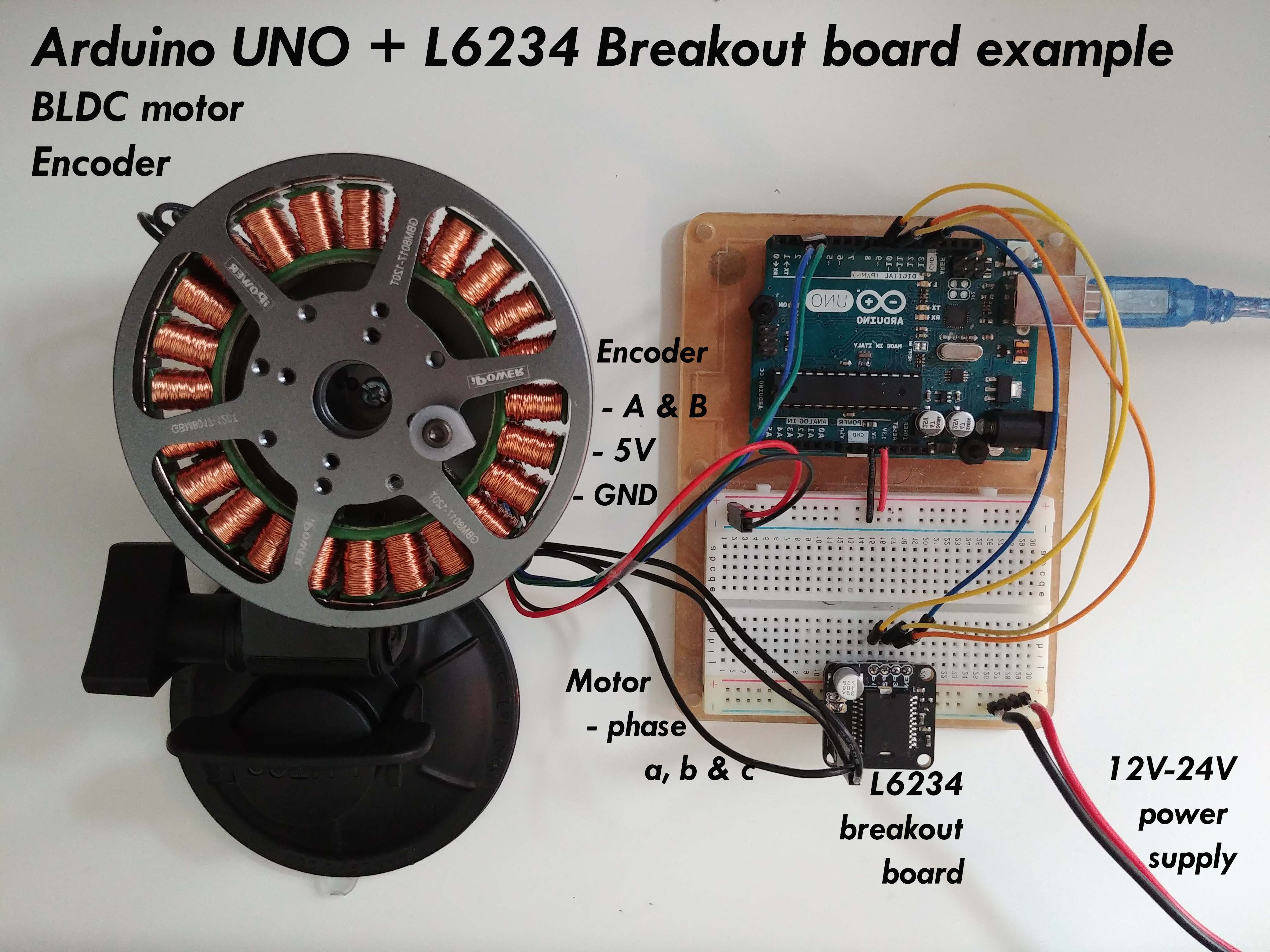

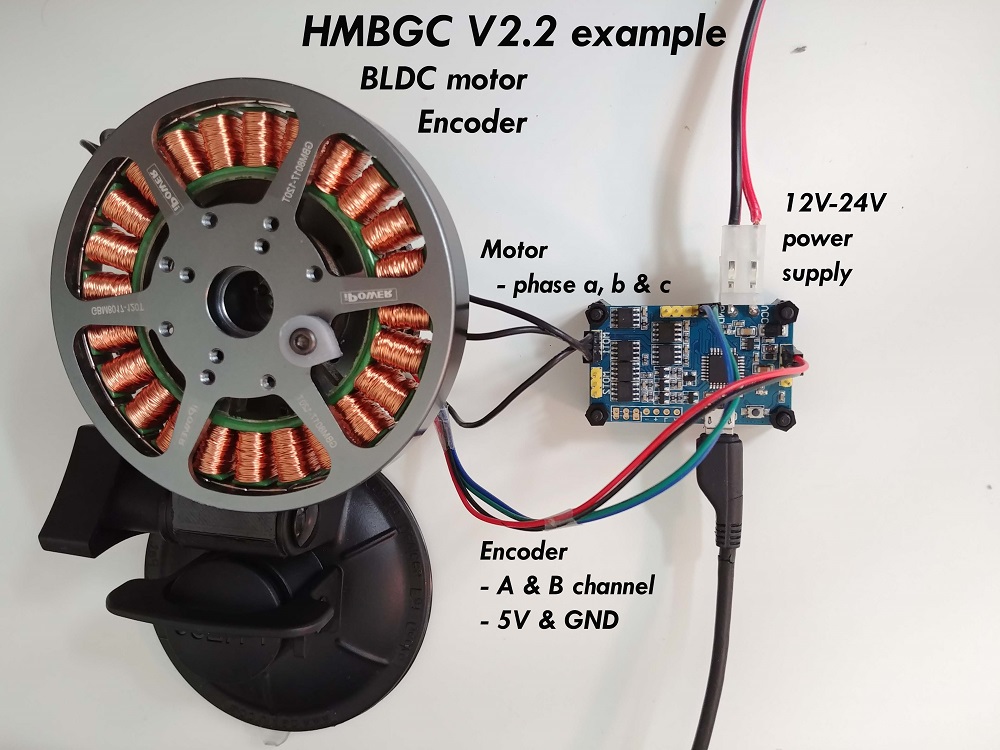

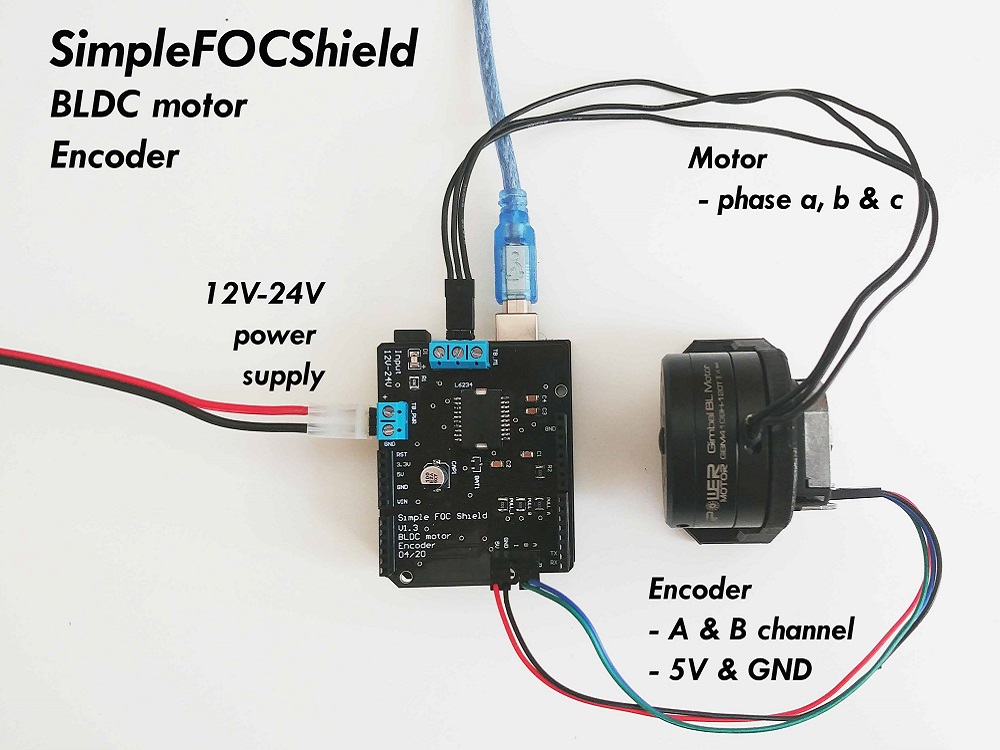

Here are some of the SimpleFOClibrary and SimpleFOCShield application examples.

We are very happy that SimpleFOClibrary has been used as a component of several research project and has made its way to several scientific papers. We are hoping that this trend is going to continue as the project matures and becomes more robust! A short resume paper about SimpleFOC has been published in the Journal of Open Source Software:

SimpleFOC: A Field Oriented Control (FOC) Library for Controlling Brushless Direct Current (BLDC) and Stepper Motors.

A. Skuric, HS. Bank, R. Unger, O. Williams, D. González-Reyes

Journal of Open Source Software, 7(74), 4232, https://doi.org/10.21105/joss.04232

If you are interested in citing SimpleFOClibrary or some other component of SimpleFOCproject in your research, we suggest you to cite our paper:

@article{simplefoc2022,

doi = {10.21105/joss.04232},

url = {https://doi.org/10.21105/joss.04232},

year = {2022},

publisher = {The Open Journal},

volume = {7},

number = {74},

pages = {4232},

author = {Antun Skuric and Hasan Sinan Bank and Richard Unger and Owen Williams and David González-Reyes},

title = {SimpleFOC: A Field Oriented Control (FOC) Library for Controlling Brushless Direct Current (BLDC) and Stepper Motors},

journal = {Journal of Open Source Software}

}