hi, here is the log while trying to connect :

Changing monitoring state from "Offline" to "Detecting serial port" Serial port list: [u'/dev/ttyACM0'] Connecting to: /dev/ttyACM0 Changing monitoring state from "Detecting serial port" to "Opening serial port" Connected to: Serial<id=0x69a46e30, open=True>(port='/dev/ttyACM0', baudrate=115200, bytesize=8, parity='N', stopbits=1, timeout=10.0, xonxoff=False, rtscts=False, dsrdtr=False), starting monitor Starting baud rate detection... Changing monitoring state from "Opening serial port" to "Detecting baudrate" Trying baudrate: 115200 Send: M5 Recv: Baudrate test retry #1 Send: M5 Recv: Grbl 1.1g ['$' for help] Changing monitoring state from "Detecting baudrate" to "Operational" Recv: [MSG:'$H'|'$X' to unlock] Recv: ok Send: $$ Recv: error:9 Changing monitoring state from "Operational" to "Error: error:9" Send: M112 Send: N1 M112*32 Send: N2 M104 T0 S0*35 Send: N3 M140 S0*102 Changing monitoring state from "Error: error:9" to "Offline (Error: error:9)" Connection closed, closing down monitor

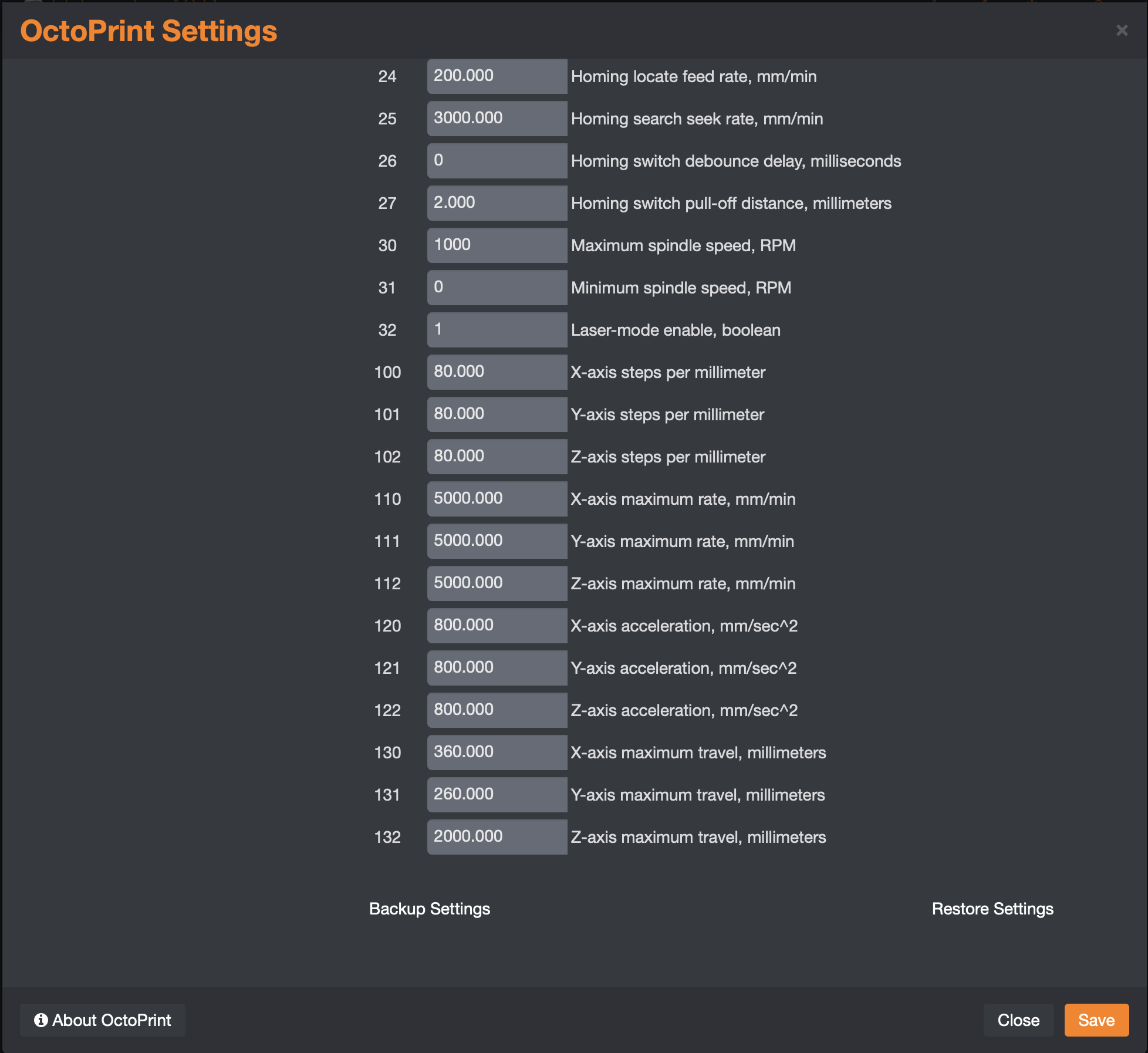

while in openbuildcontrols I got :

Checking for Updates [19:09:48] [ Update Available! ] OpenBuilds CONTROL 1.0.233. is available now. [19:09:48] [ Update Available! ] Download will start in 0 seconds (cancel) [19:09:48] [ Update Available! ] You will be prompted when its ready to be installed [19:09:54] [ connect ] PORT INFO: Port is now open: /dev/ttyACM0 - Attempting to detect Firmware [19:09:54] [ connect ] Checking for firmware on /dev/ttyACM0 [19:09:54] [ connect ] Detecting Firmware: Method 1 (Autoreset) [19:09:55] [ connect ] Detecting Firmware: Method 2 (Ctrl+X) [19:09:56] [ connect ] Detecting Firmware: Method 3 (others that are not supported) [19:09:56] [ ] Grbl 1.1g ['$' for help] [19:09:56] [ ] [MSG:'$H'|'$X' to unlock] [19:09:57] [ $$ ] $0=10 ;Step pulse time, microseconds [19:09:57] [ $$ ] $1=255 ;Step idle delay, milliseconds [19:09:57] [ $$ ] $2=0 ;Step pulse invert, mask [19:09:57] [ $$ ] $3=3 ;Step direction invert, mask [19:09:57] [ $$ ] $4=0 ;Invert step enable pin, boolean [19:09:57] [ $$ ] $5=0 ;Invert limit pins, boolean [19:09:57] [ $$ ] $6=0 ;Invert probe pin, boolean [19:09:57] [ $$ ] $10=1 ;Status report options, mask [19:09:57] [ $$ ] $11=0.020 ;Junction deviation, millimeters [19:09:57] [ $$ ] $12=0.002 ;Arc tolerance, millimeters [19:09:57] [ $$ ] $13=0 ;Report in inches, boolean [19:09:57] [ $$ ] $20=0 ;Soft limits enable, boolean [19:09:57] [ $$ ] $21=0 ;Hard limits enable, boolean [19:09:57] [ $$ ] $22=1 ;Homing cycle enable, boolean [19:09:57] [ $$ ] $23=3 ;Homing direction invert, mask [19:09:57] [ $$ ] $24=25.000 ;Homing locate feed rate, mm/min [19:09:57] [ $$ ] $25=750.000 ;Homing search seek rate, mm/min [19:09:57] [ $$ ] $26=250 ;Homing switch debounce delay, milliseconds [19:09:57] [ $$ ] $27=1.000 ;Homing switch pull-off distance, millmeters [19:09:57] [ $$ ] $30=12000 ;Maximum spindle speed, RPM [19:09:57] [ $$ ] $31=0 ;Minimum spindle speed, RPM [19:09:57] [ $$ ] $32=0 ;Laser-mode enable, boolean [19:09:57] [ $$ ] $100=40.000 ;X-axis steps per millimeter [19:09:57] [ $$ ] $101=40.000 ;Y-axis steps per millimeter [19:09:57] [ $$ ] $102=188.947 ;Z-axis steps per millimeter [19:09:57] [ $$ ] $110=8000.000 ;X-axis maximum rate, mm/min [19:09:57] [ $$ ] $111=8000.000 ;Y-axis maximum rate, mm/min [19:09:57] [ $$ ] $112=500.000 ;Z-axis maximum rate, mm/min [19:09:57] [ $$ ] $120=500.000 ;X-axis acceleration, mm/sec^2 [19:09:57] [ $$ ] $121=500.000 ;Y-axis acceleration, mm/sec^2 [19:09:57] [ $$ ] $122=50.000 ;Z-axis acceleration, mm/sec^2 [19:09:57] [ $$ ] $130=740.000 ;X-axis maximum travel, millimeters [19:09:57] [ $$ ] $131=790.000 ;Y-axis maximum travel, millimeters [19:09:57] [ $$ ] $132=100.000 ;Z-axis maximum travel, millimeters [19:09:57] [ $$ ] ok [19:09:57] [ $I ] [VER:1.1g.20181112:] [19:09:57] [ $I ] [OPT:V,15,128] [19:09:57] [ $I ] ok [19:09:58] [ autoupdate ] Starting update... Please wait [19:09:58] [ connect ] Firmware Detected: grbl version 1.1g on /dev/ttyACM0 [19:10:00] [ autoupdate ] Starting Download: v1.0.233 [19:10:13] [ autoupdate ] New update ready [19:10:42] [ disconnect ] PORT INFO: Port closed

version of GRBL is 1.1g

any test i can perform ?